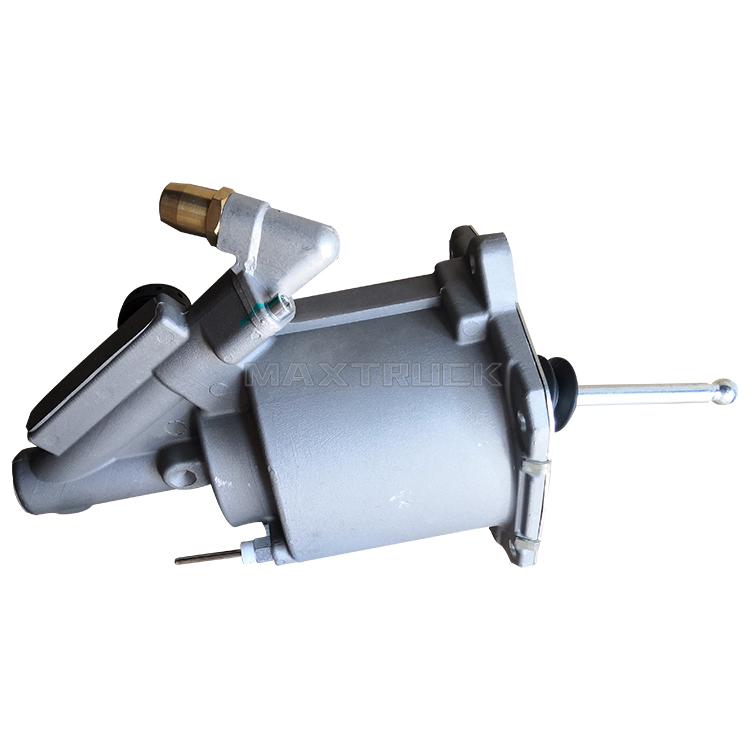

The clutch servo is a vital component in the

transmission system of modern trucks. For fleets and owner-operators alike, understanding the importance of regular clutch servo maintenance can mean the difference between uninterrupted deliveries and costly downtime. At MAXTRUCK GROUP LIMITED (MAXTRUCK), we have seen firsthand how proactive care can extend the life of your vehicle and optimize its performance. In this article, we’ll discuss why clutch servo maintenance should be a top priority, dive into related industry trends, and highlight how the right truck spare parts and clutch servo choices can keep your fleet moving efficiently.

The Role of the Clutch Servo in Modern Trucks

The clutch servo is a pneumatic or hydraulic device that assists in disengaging the clutch, making gear changes smoother and reducing the physical effort required by the driver. In heavy-duty trucks, where clutch operation can be frequent and demanding, the clutch servo not only improves comfort but also protects the transmission system from excessive wear.

MAXTRUCK has observed that as trucks become more advanced, the demands placed on their components grow. The clutch servo, therefore, is not just a convenience—it’s a critical part of the overall driveline system, ensuring that power transfer from the

engine to the wheels is seamless and reliable.

Why Regular Maintenance Matters

Neglecting clutch servo maintenance can lead to a host of problems: increased pedal effort, erratic gear shifts, premature clutch wear, and even total clutch failure. These issues can result in unexpected breakdowns, expensive repairs, and lost revenue due to vehicle downtime. Regular inspections and timely replacement of worn parts can prevent these problems.

At MAXTRUCK, we recommend routine checks for leaks, wear, and proper operation. Our service experts advise replacing the clutch servo at manufacturer-recommended intervals or sooner if performance issues arise. Using high-quality truck spare parts, specifically designed for your vehicle model, is essential for optimal performance and longevity.

Key Benefits of Clutch Servo Maintenance

- Improved Safety: A well-maintained clutch servo ensures predictable clutch operation, reducing the risk of accidents caused by missed or delayed gear shifts.

- Cost Savings: Preventative maintenance is far less expensive than major repairs or unplanned breakdowns.

- Extended Component Life: Regular care reduces wear and tear on related parts, including the clutch disc, pressure plate, and transmission.

- Driver Comfort: Smooth clutch operation reduces fatigue, especially on long hauls or in stop-and-go traffic.

Industry Trends: The Evolution of Clutch Servo Technology

The commercial trucking industry is witnessing rapid advancements in driveline technology. Automated manual transmissions (AMTs) and electronically controlled clutch servos are becoming standard in many new trucks. These systems require even more precise maintenance, as electronic sensors and actuators can be sensitive to dirt, moisture, and wear.

MAXTRUCK is at the forefront of these changes, offering support and truck spare parts compatible with both traditional and modern clutch servo systems. Our commitment to quality ensures that our customers can confidently navigate the shift toward automation and increased efficiency.

How Poor Maintenance Impacts Fleet Operations

For fleet operators, the cost of unplanned downtime can be staggering. A single out-of-service truck can mean missed deliveries, lost contracts, and reputational damage. Poorly maintained clutch servos are a leading cause of transmission-related breakdowns. Investing in regular maintenance not only protects your vehicles but also your business reputation.

MAXTRUCK works closely with logistics companies to develop maintenance schedules tailored to their specific operating conditions. Our experts can help identify early warning signs of clutch servo issues and recommend the right clutch servo replacements to minimize disruptions.

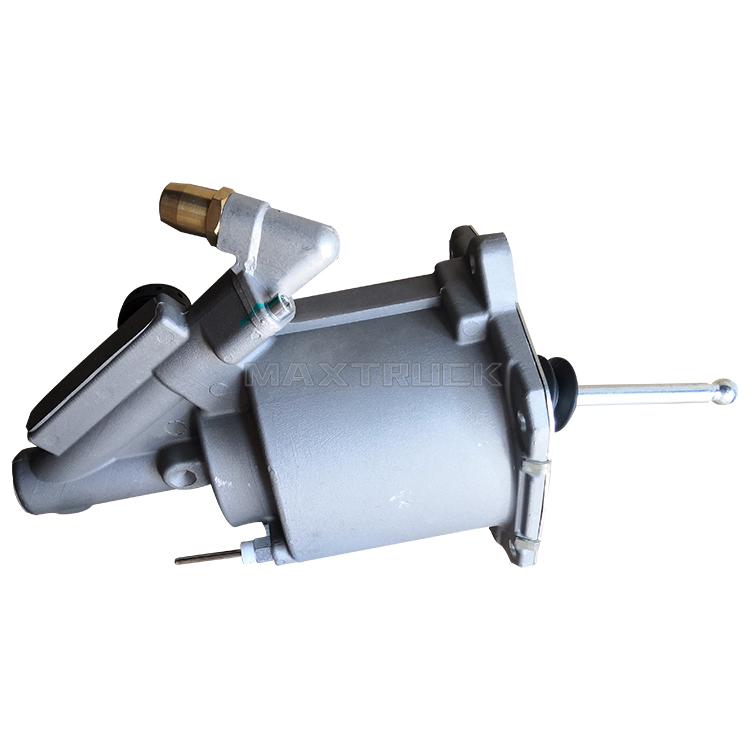

Choosing the Right Truck Spare Parts

Not all spare parts are created equal. Using substandard or incompatible parts can compromise the safety and reliability of your truck. At MAXTRUCK, we supply OEM-quality and aftermarket truck spare parts that meet or exceed manufacturer specifications. Our rigorous quality control processes ensure that every part, including the clutch servo, delivers dependable performance.

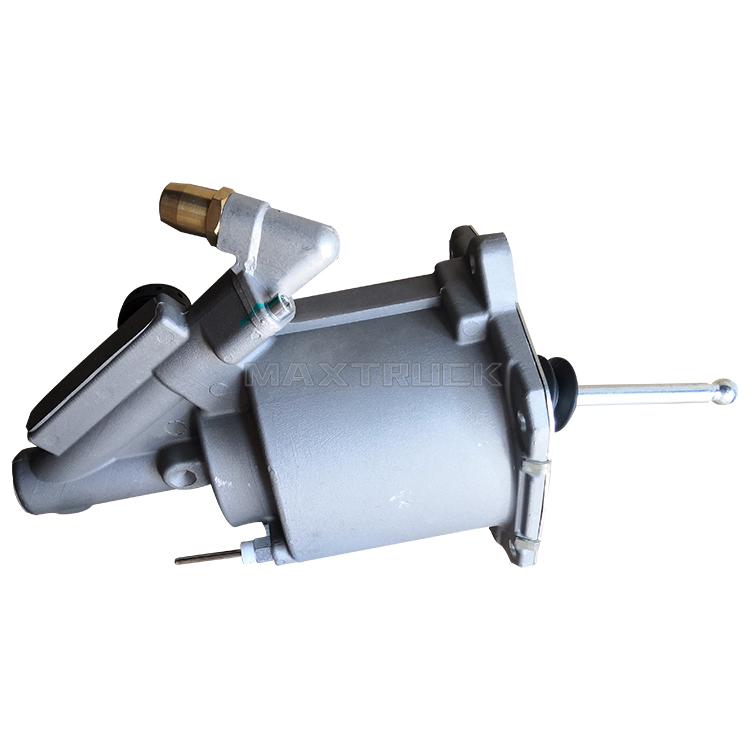

Signs Your Clutch Servo Needs Attention

- Increased Pedal Effort: If the clutch feels heavier or harder to operate, the servo may be losing efficiency.

- Delayed Engagement: Hesitation when shifting gears can indicate a failing clutch servo.

- Fluid Leaks: Hydraulic servos may develop leaks, leading to a drop in system pressure.

- Unusual Noises: Grinding or hissing sounds during clutch operation can signal internal wear or air leaks.

Best Practices for Clutch Servo Maintenance

MAXTRUCK recommends the following steps to keep your clutch servo in top condition:

- Regular Inspections: Check for leaks, corrosion, and proper function during routine service intervals.

- Timely Replacement: Don’t wait for total failure. Replace worn or damaged servos with high-quality parts.

- Cleanliness: Keep hydraulic and pneumatic systems free of contaminants that can cause premature wear.

- Use Recommended Fluids: Always use manufacturer-approved hydraulic fluids or lubricants.

- Driver Training: Educate drivers about the signs of clutch servo issues and encourage prompt reporting.

Industry Insights: The Cost of Downtime

Industry research shows that the average cost of truck downtime can exceed $1,000 per day, not including the long-term impact on customer relationships. Proactive maintenance of critical components like the clutch servo is a small investment compared to the financial and operational risks of breakdowns.

MAXTRUCK has helped numerous clients reduce their maintenance costs and improve vehicle uptime by supplying reliable truck spare parts and offering technical support tailored to each fleet’s unique needs.

Future Developments in Clutch Servo Technology

As the trucking industry embraces electrification and autonomous driving technologies, the role of the clutch servo is evolving. Future systems may integrate advanced sensors, self-diagnosing capabilities, and predictive maintenance alerts. MAXTRUCK is actively involved in research and development to ensure our customers have access to the latest innovations and compatible clutch servo solutions.

Staying ahead of these trends is essential for fleet managers who want to future-proof their operations. By partnering with a forward-thinking supplier like MAXTRUCK, you can be confident that your trucks will remain competitive and compliant with emerging industry standards.

Case Study: How Regular Maintenance Saved a Fleet

One of MAXTRUCK’s logistics clients recently implemented a comprehensive clutch servo maintenance program across their fleet of 50 trucks. Within six months, they reported a 30% reduction in transmission-related breakdowns and a significant increase in driver satisfaction. By using genuine truck spare parts and adhering to a strict maintenance schedule, they avoided costly emergency repairs and kept their vehicles on the road.

Conclusion: Make Clutch Servo Maintenance a Priority

Regular maintenance of your truck’s clutch servo is not just a technical requirement—it’s a strategic business decision. By investing in proactive care, using quality truck spare parts, and staying informed about industry trends, you can protect your vehicles, your drivers, and your bottom line.

MAXTRUCK GROUP LIMITED is committed to supporting fleet operators and owner-operators with the best in parts, service, and expertise. Don’t let a neglected clutch servo bring your operations to a halt. Contact MAXTRUCK today to learn more about our products and maintenance solutions.

Frequently Asked Questions

| How often should I service my clutch servo? |

Follow your manufacturer’s recommendations, but inspect at every major service interval or if you notice performance changes. |

| Can I use aftermarket parts for my clutch servo? |

Yes, provided they meet or exceed OEM standards. MAXTRUCK offers both OEM and high-quality aftermarket options. |

| What are the risks of ignoring clutch servo maintenance? |

Risks include increased wear, higher repair costs, breakdowns, and safety hazards. |

| Does MAXTRUCK provide technical support? |

Absolutely. We offer expert guidance on part selection, installation, and maintenance best practices. |

For more industry insights and maintenance tips, stay connected with MAXTRUCK GROUP LIMITED—your trusted partner in reliable truck spare parts and clutch servo solutions.