Industry

How to Diagnose and Fix Common Air Compressor Problems in Trucks

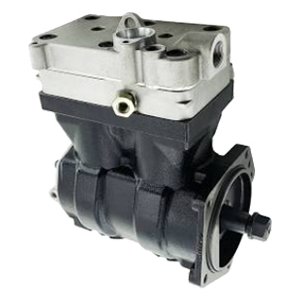

Air compressors are the heart of pneumatic systems in trucks, playing a vital role in braking, suspension, and other essential operations. For fleet managers and truck owners, understanding how to diagnose and fix common air compressor problems is key to ensuring safety, efficiency, and cost-effectiveness. As a leading supplier of commercial truck parts and solutions, MAXTRUCK GROUP LIMITED (MAXTRUCK) brings you this comprehensive guide to identifying, troubleshooting, and resolving air compressor issues, while sharing industry insights and the importance of truck air dryer and air brake compressor systems.

Understanding the Role of Air Compressors in Trucks

The air compressor is responsible for converting power from the truck’s engine into compressed air, which is then stored in reservoirs and used to operate air brakes, suspension systems, and other pneumatic devices. Without a properly functioning air compressor, a truck’s safety and performance are compromised, leading to potential breakdowns, compliance issues, and costly repairs.

- Primary Function: Supplies compressed air for braking systems and auxiliary equipment.

- Integration: Works in tandem with truck air dryer units to remove moisture, and with air brake compressor assemblies for reliable operation.

- Critical Safety Component: Ensures consistent brake pressure and quick response times, especially in heavy-duty trucks.

Common Air Compressor Problems in Trucks

At MAXTRUCK, we often encounter a range of air compressor issues across different truck models and fleets. Here are the most frequent problems:

- Insufficient Air Pressure: The compressor fails to build up enough pressure for the air brake system, leading to warning lights or alarms.

- Excessive Oil Consumption: Oil leaks into the air system, contaminating components and reducing efficiency.

- Unusual Noises: Grinding, knocking, or hissing sounds indicate internal wear or external leaks.

- Overheating: The compressor runs hot, risking damage to seals and internal parts.

- Continuous Running: The compressor doesn’t unload or cut out, leading to unnecessary wear and energy waste.

- Moisture in the Air System: Failure of the truck air dryer leads to water contamination, risking brake failure and corrosion.

Diagnosing Air Compressor Issues

A systematic approach is essential for accurate diagnosis. MAXTRUCK recommends the following steps:

1. Visual Inspection

- Check for oil leaks around the compressor and connected air lines.

- Look for signs of corrosion, loose fittings, or damaged hoses.

- Inspect the truck air dryer for water or oil residue in the purge valve area.

2. Listen for Unusual Sounds

- Start the engine and listen for abnormal noises from the compressor.

- Identify grinding or knocking, which may indicate internal damage.

3. Monitor System Pressure

- Check dashboard gauges for proper pressure build-up (typically 100-125 psi for most trucks).

- If pressure builds slowly or not at all, suspect leaks or a failing air brake compressor.

4. Check for Moisture and Contaminants

- Drain air tanks and observe the expelled air for water or oil.

- Frequent water presence points to a faulty truck air dryer or excessive compressor blow-by.

5. Inspect Compressor Drive and Controls

- Ensure belts (if applicable) are tight and undamaged.

- Test the governor and unloader valve for correct operation.

Fixing Common Air Compressor Problems

Once the problem has been identified, MAXTRUCK recommends the following repair strategies:

1. Low Air Pressure

- Action: Check for air leaks in hoses, fittings, and valves. Replace or tighten as needed.

- Compressor Output: If output remains low, inspect the air brake compressor for worn piston rings or valves; overhaul or replace the unit if necessary.

2. Excessive Oil in System

- Action: Replace faulty seals or worn piston rings in the compressor.

- Maintenance: Regularly service the truck air dryer to prevent oil carryover into the air system.

3. Unusual Noises

- Action: Remove and inspect the compressor for internal wear, broken components, or foreign objects.

- Solution: Repair or replace the compressor as needed.

4. Overheating

- Action: Check for blocked cooling fins, low engine coolant, or restricted air flow around the compressor.

- Solution: Restore proper cooling and replace any damaged parts.

5. Continuous Running Compressor

- Action: Test the governor and unloader valves for correct operation; replace if faulty.

- System Check: Inspect for air leaks that may prevent the system from reaching cut-out pressure.

6. Moisture in Air System

- Action: Service or replace the truck air dryer cartridge or assembly.

- Prevention: Drain air tanks daily, especially in humid climates or during winter months.

Preventive Maintenance for Truck Air Compressors

At MAXTRUCK, we advocate for a proactive maintenance schedule to minimize compressor failures and extend component life. Here’s what to include in your routine:

- Daily: Drain air tanks to remove moisture and contaminants.

- Weekly: Inspect air lines, fittings, and the truck air dryer for leaks or signs of wear.

- Monthly: Check compressor mounting bolts, belts, and cooling systems.

- Quarterly: Test system pressure build-up and governor operation.

- Semi-Annually: Replace truck air dryer cartridges and inspect the air brake compressor for internal wear.

Industry Trends and Innovations in Air Compressor Technology

The commercial trucking industry is evolving rapidly, with advances in air compressor efficiency, reliability, and integration. Leading manufacturers and suppliers like MAXTRUCK are at the forefront of these developments.

- Electronic Control: Modern air compressors feature electronic governors and diagnostics, enabling real-time monitoring and predictive maintenance.

- Integrated Air Dryer Systems: The latest truck air dryer units are combined with compressors for compact installation and improved moisture removal.

- Lightweight Materials: Aluminum and composite housings reduce weight, improving fuel efficiency and payload capacity.

- Environmental Compliance: New compressors are designed for lower emissions and reduced oil carryover, aligning with global environmental standards.

- Aftermarket Support: Companies like MAXTRUCK provide a full range of OEM and aftermarket air brake compressor and truck air dryer parts for all major truck brands.

As regulatory requirements become stricter and fleet operators demand greater uptime, investing in high-quality air compressor systems and maintenance services is more important than ever.

Why Choose MAXTRUCK for Your Air Compressor Needs?

With decades of industry experience, MAXTRUCK GROUP LIMITED is a trusted partner for truck fleets and independent operators worldwide. Our expertise covers:

- Comprehensive inventory of air brake compressor and truck air dryer units.

- Expert technical support and troubleshooting guides.

- Fast delivery and global logistics network.

- Customized solutions for specific fleet requirements.

- Commitment to quality, safety, and customer satisfaction.

Whether you operate a small fleet or manage hundreds of vehicles, MAXTRUCK delivers the parts, knowledge, and support you need to keep your trucks on the road and your business moving forward.

Conclusion

Diagnosing and fixing air compressor problems in trucks is critical to safe and efficient operations. By following the steps outlined above and partnering with industry leaders like MAXTRUCK GROUP LIMITED, you can ensure your fleet’s pneumatic systems remain reliable and compliant. Don’t overlook the importance of regular maintenance and the role of quality truck air dryer and air brake compressor components. For expert advice, OEM parts, and world-class service, trust MAXTRUCK—your partner in commercial vehicle solutions.

Tags:electric system,brake system