Industry

How Air Compressors Help Prevent Freezing in Your Truck’s Air Lines

When winter sets in and temperatures plummet, truck owners and fleet managers face a significant challenge: keeping their vehicles in optimal working condition. One of the most common issues in cold climates is the freezing of air lines in trucks. At MAXTRUCK GROUP LIMITED (abbreviated as MAXTRUCK), we understand how critical it is to prevent this problem and keep your trucks running smoothly throughout the harshest months. In this article, we’ll explore how air compressors play a vital role in preventing freezing in your truck’s air lines, and why investing in high-quality truck air compressors and truck air dryers is essential for your fleet’s reliability and safety.

Understanding the Problem: Why Do Truck Air Lines Freeze?

Truck air lines are an integral part of the braking system and other pneumatic controls. These lines carry compressed air generated by the truck’s air compressor. However, during cold weather, moisture in the compressed air can condense and freeze inside the air lines, leading to blockages or even brake failure. This can pose serious safety risks and result in costly downtime, repairs, and delays.

The Role of Air Compressors in Truck Air Systems

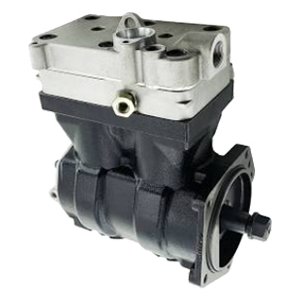

Air compressors are the heart of a truck’s pneumatic system. They generate and supply compressed air for the brakes, suspension, and other critical functions. But their role goes beyond just providing air pressure; they are also key to managing moisture in the air system. At MAXTRUCK, we design and manufacture advanced truck air compressors that not only deliver reliable performance but also help prevent the accumulation of moisture that leads to freezing.

How Air Compressors Work in Cold Conditions

In cold weather, air compressors must work harder to maintain proper air pressure and quality. Modern compressors, such as those offered by MAXTRUCK, are equipped with features that help minimize moisture content in the compressed air. This is achieved through efficient compression processes and integration with air dryers, which we’ll discuss in detail later.

The Importance of Truck Air Dryers

One of the most effective ways to prevent freezing in truck air lines is by using a high-quality truck air dryer. This device is installed between the air compressor and the air tanks, and its primary function is to remove moisture and contaminants from the compressed air before it enters the air system.

- Moisture Removal: Air dryers use desiccant materials to absorb water vapor, ensuring that only dry air circulates through the air lines.

- Contaminant filtration: They also filter out oil, dirt, and other impurities that can damage the air system.

- Automatic Purge: Many modern air dryers feature automatic purge cycles that expel collected moisture, further reducing the risk of freezing.

At MAXTRUCK, our truck air dryers are engineered for maximum efficiency and durability, making them an essential addition to any truck operating in cold climates.

Why Truck Air Compressors and Air Dryers Go Hand-in-Hand

While a robust air compressor is necessary for generating pressure, it’s the combination with a reliable air dryer that truly safeguards your truck’s air system from freezing. Together, they ensure that the air entering your lines is both pressurized and dry, significantly reducing the likelihood of ice formation.

Industry Insights: The Impact of Frozen Air Lines on Trucking Operations

The trucking industry is the backbone of logistics and supply chains worldwide. Downtime caused by frozen air lines can have a ripple effect, leading to missed deliveries, increased operational costs, and even safety hazards. According to industry data, winter-related air system failures account for a significant percentage of roadside breakdowns during the colder months.

Cost Implications of Air System Failures

Repairing frozen or damaged air lines is not only expensive but also time-consuming. It often requires towing, replacement of parts, and lost productivity. Proactive investment in quality air compressors and air dryers from trusted manufacturers like MAXTRUCK can save fleets thousands of dollars annually by preventing these issues before they occur.

Safety Considerations

Beyond financial costs, the safety of drivers and cargo is paramount. Frozen air lines can compromise braking efficiency, increasing the risk of accidents. Regulatory bodies and insurance companies are placing greater emphasis on preventive maintenance, making it more important than ever for fleet operators to prioritize air system health.

Choosing the Right Truck Air Compressor and Air Dryer

Selecting the right equipment is essential for ensuring optimal performance in all weather conditions. When evaluating truck air compressors and air dryers, consider the following factors:

- Capacity: Ensure the compressor can meet the air demand of your vehicle’s systems.

- Efficiency: Look for energy-efficient models that minimize fuel consumption.

- Durability: Equipment should be built to withstand harsh environments and frequent use.

- Compatibility: Verify that the air compressor and air dryer are compatible with your truck’s make and model.

MAXTRUCK offers a comprehensive range of truck air compressors and truck air dryers, designed with the latest technology to ensure reliability and ease of maintenance. Our products undergo rigorous testing to meet international standards and deliver consistent performance in even the most demanding conditions.

Innovations in Air System Technology

The commercial vehicle industry is witnessing continuous advancements in air system technology. Smart compressors with integrated sensors can monitor air quality and moisture levels in real time, alerting operators to potential issues before they escalate. At MAXTRUCK, we are at the forefront of these innovations, offering solutions that enhance safety, efficiency, and peace of mind for fleet operators.

Best Practices for Preventing Frozen Air Lines

While investing in quality equipment is crucial, following best practices for maintenance and operation can further reduce the risk of freezing. Here are some recommendations from the experts at MAXTRUCK:

- Regular Inspections: Check air lines, compressors, and dryers for signs of wear or damage.

- Drain Air Tanks Daily: Manually or automatically draining air tanks removes accumulated moisture.

- Replace Desiccant Cartridges: Air dryers rely on desiccant material that needs periodic replacement.

- Monitor System Pressure: Low pressure can indicate leaks or blockages caused by ice.

- Warm-Up Procedures: Allow the engine and air system to warm up before driving in extremely cold conditions.

By adhering to these practices and using reliable truck air compressors and truck air dryers from MAXTRUCK, you can minimize the risk of winter-related air system failures.

Case Study: Real-World Benefits for Fleet Operators

A leading logistics company in Northern Europe faced recurring issues with frozen air lines during winter, resulting in frequent breakdowns and delivery delays. After equipping their fleet with MAXTRUCK air compressors and air dryers, they reported a dramatic reduction in air system failures. The improved reliability not only enhanced safety but also boosted customer satisfaction and operational efficiency.

| Before MAXTRUCK | After MAXTRUCK |

|---|---|

| Frequent air line freezing | Minimal freezing incidents |

| High repair costs | Reduced maintenance expenses |

| Missed deliveries | Improved on-time performance |

Feedback from the Field

Drivers and technicians praised the ease of installation and the noticeable improvement in air system performance. This case exemplifies how proactive investment in advanced air system components can yield significant returns for fleet operators.

Looking Ahead: The Future of Truck Air Systems

As environmental regulations tighten and the push for efficiency grows, the trucking industry will continue to evolve. Innovations in air compressor and dryer technology, such as integrated diagnostics and energy-saving features, will become standard. MAXTRUCK remains committed to developing solutions that not only prevent freezing but also contribute to greener, more sustainable transport.

Conclusion

Freezing air lines are a serious concern for truck operators, especially in regions with harsh winters. By investing in high-quality truck air compressors and truck air dryers from MAXTRUCK, you can protect your fleet from costly breakdowns, enhance safety, and ensure uninterrupted operations. Coupled with regular maintenance and best practices, these components form the backbone of a reliable, winter-ready air system.

For more information on MAXTRUCK GROUP LIMITED’s full range of air compressors and air dryers, or to speak with an expert about your fleet’s needs, contact us today. Don’t let winter weather put your operations at risk—choose MAXTRUCK for performance you can trust, season after season.