Industry

How a Faulty Clutch Servo Can Affect Your Truck’s Clutch Operation

The clutch system is the heart of any commercial truck’s transmission. At MAXTRUCK GROUP LIMITED (MAXTRUCK), we understand that even a minor fault in this system can lead to significant operational issues, unexpected downtime, and increased maintenance costs. One critical, yet often overlooked, component is the clutch servo. In this article, we’ll explore how a faulty clutch servo can impact your truck’s clutch operation, discuss the importance of timely maintenance, and provide insights into industry trends and solutions.

Understanding the Clutch Servo: Its Role and Importance

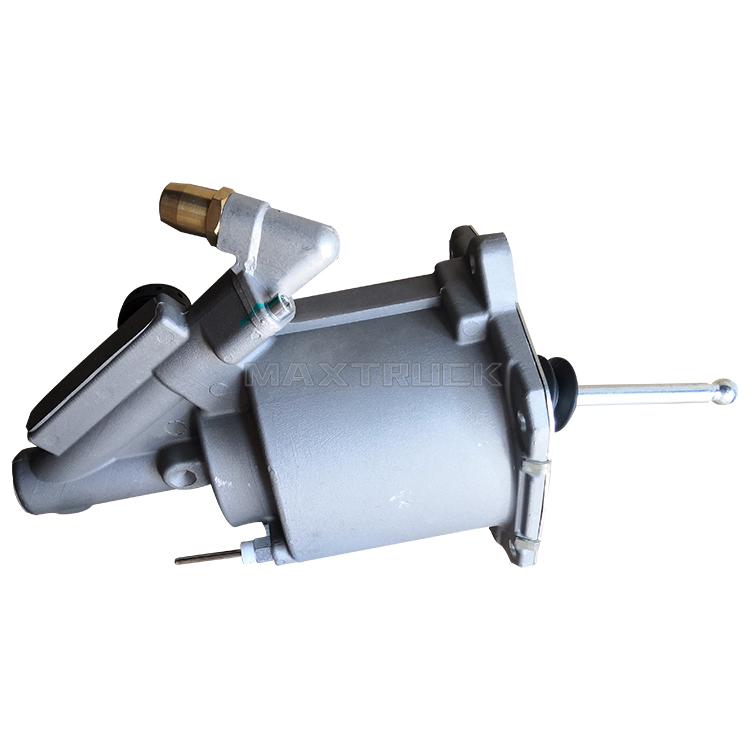

The clutch servo is a pneumatic or hydraulic device designed to assist the driver in operating the clutch with minimal effort. In heavy-duty trucks, where clutch pressures are high, the servo’s assistance is essential for smooth gear changes and driver comfort. At MAXTRUCK, we often see that the health of the clutch servo is directly linked to the overall performance and longevity of the clutch system.

- Reduces Driver Fatigue: By amplifying the force applied by the driver, the servo makes clutch operation smoother and less physically demanding.

- Ensures Smooth Gear Shifts: A properly functioning servo allows for precise engagement and disengagement of the clutch, which is vital for transmission health.

- Protects Drivetrain Components: By providing controlled and consistent clutch operation, the servo helps reduce shock loads on the transmission and other drivetrain parts.

How a Faulty Clutch Servo Affects Clutch Operation

A malfunctioning clutch servo can introduce a host of problems for your truck’s clutch system. At MAXTRUCK, our technicians have identified several common symptoms and their potential consequences:

1. Increased Pedal Effort

When the clutch servo fails, drivers may notice that the clutch pedal becomes much harder to press. This increased effort can lead to driver fatigue, especially during long-haul operations or in stop-and-go traffic. Over time, this strain can cause drivers to avoid proper clutch use, leading to premature clutch wear.

2. Inconsistent Clutch Engagement

A faulty servo can result in uneven or jerky clutch engagement. This not only makes driving uncomfortable but can also cause excessive wear on the clutch disc and pressure plate. In severe cases, it may even lead to clutch slippage, which can damage the flywheel and transmission input shaft.

3. Delayed or Failed Gear Shifts

Smooth gear changes rely on the clutch disengaging and engaging at the right moments. A malfunctioning servo can disrupt this timing, making it difficult to shift gears or causing grinding noises during shifts. Such issues can accelerate transmission wear and lead to costly repairs.

4. Air or Hydraulic Leaks

Many clutch servos operate using air or hydraulic pressure. Leaks in the system can reduce the servo’s effectiveness, resulting in erratic clutch operation. In pneumatic systems, air leaks can also affect other components that rely on the truck’s air supply, such as brakes and suspension.

5. Complete Clutch Failure

In extreme cases, a failed clutch servo can prevent the clutch from disengaging entirely. This can make it impossible to change gears or even move the truck, leading to breakdowns and unplanned downtime.

Industry Trends: Clutch Servos and Modern Trucking

The commercial vehicle industry is evolving rapidly, with a strong focus on automation, driver comfort, and efficiency. At MAXTRUCK, we are at the forefront of integrating advanced clutch servo technologies into our fleet solutions. In recent years, two key trends have emerged:

- Integration with Automated Manual Transmissions (AMTs): Modern trucks increasingly use AMTs, which rely on precise servo operation for seamless gear changes. A faulty servo in such systems can lead to erratic shifts or system errors, highlighting the need for reliable components and regular diagnostics.

- Telematics and Predictive Maintenance: Fleet operators are leveraging telematics to monitor clutch operation in real-time. Predictive analytics can identify early signs of servo failure, allowing for proactive maintenance and minimizing downtime.

As commercial fleets become more data-driven, the importance of maintaining every component—including the clutch servo—cannot be overstated. MAXTRUCK’s service teams are equipped with the latest diagnostic tools to ensure your trucks stay on the road and operate at peak efficiency.

Diagnosing and Addressing Clutch Servo Issues

Early detection of clutch servo problems can prevent minor issues from escalating into major failures. Here are some signs and steps to consider:

Common Symptoms of a Faulty Clutch Servo

- Stiff or spongy clutch pedal feel

- Unusual noises during clutch operation

- Difficulty shifting gears

- Visible leaks under the truck (air or hydraulic fluid)

- Warning lights or error codes (in trucks with AMTs)

Inspection and Maintenance Tips

- Visual Inspection: Regularly check for leaks, damaged hoses, or loose connections around the clutch servo.

- Listen for Air Leaks: In pneumatic systems, a hissing sound may indicate escaping air from the servo or associated lines.

- Check Clutch Pedal Travel: Excessive free play or resistance can signal servo issues.

- Consult Diagnostic Codes: Modern trucks may log faults related to servo or clutch operation.

MAXTRUCK recommends scheduling regular inspections as part of your preventive maintenance program. Addressing clutch servo issues early can save time, money, and prevent roadside breakdowns.

The Importance of Genuine Parts and Professional Service

When replacing a faulty clutch servo, it’s crucial to use genuine, manufacturer-approved parts. At MAXTRUCK, we only supply and install OEM or high-quality aftermarket components to ensure reliability and compatibility with your truck’s systems.

- Quality Assurance: Genuine parts are designed to meet strict performance and safety standards.

- Warranty Protection: Using approved parts helps maintain your vehicle’s warranty coverage.

- Long-Term Reliability: Professional installation by trained technicians reduces the risk of future failures.

Our MAXTRUCK service centers employ experienced mechanics who understand the intricacies of clutch systems in commercial vehicles. We invest in ongoing training and state-of-the-art diagnostic equipment to deliver industry-leading service.

Industry Insights: The Future of Clutch Technology

As the trucking industry embraces electrification, alternative fuels, and automation, clutch systems are also evolving. Some key developments include:

- Electro-Hydraulic Clutch Actuators: These systems replace traditional servos with electronically controlled actuators, enabling even finer control and integration with advanced driver assistance systems (ADAS).

- Clutch-by-Wire: Future commercial vehicles may feature fully electronic clutch controls, reducing mechanical complexity and enabling remote diagnostics.

- Improved Durability: Advances in materials and design are extending clutch and servo lifespans, reducing total cost of ownership for fleet operators.

At MAXTRUCK, we stay ahead of these trends to offer our clients the most reliable and innovative solutions. Whether you operate a single truck or a nationwide fleet, our expertise ensures you benefit from the latest industry advancements.

Clutch Servo Replacement: What to Expect

If your truck requires a clutch servo replacement, here’s what the process typically involves at a MAXTRUCK service center:

- Initial Diagnosis: Inspection and diagnostic checks to confirm the servo is at fault.

- Component Removal: Safe disconnection and removal of the old servo, ensuring no damage to adjacent parts.

- Installation: Fitting a new, genuine clutch servo, followed by system bleeding (for hydraulic systems) or pressurization (for pneumatic systems).

- Testing: Functional checks to ensure smooth clutch operation and no leaks or abnormal noises.

- Final Report: A detailed summary of work performed, including recommendations for ongoing maintenance.

Our goal at MAXTRUCK is to minimize your downtime and get your truck back on the road safely and efficiently.

Related Components: Clutch Master Cylinder & Air Brake Compressor

The clutch servo does not operate in isolation. Two other critical components often associated with clutch operation are the clutch master cylinder and the air brake compressor.

- Clutch Master Cylinder: This component generates the hydraulic pressure needed to operate the clutch servo in hydraulic systems. If the master cylinder is faulty, it can mimic or compound servo issues, leading to poor clutch performance.

- Air Brake Compressor: In pneumatic systems, the air brake compressor supplies the air pressure required by the clutch servo. A failing compressor can reduce servo effectiveness, affecting both clutch and braking performance.

MAXTRUCK recommends a holistic approach to clutch system maintenance. Regularly inspecting related components like the clutch master cylinder and air brake compressor ensures that your entire system functions flawlessly, reducing the risk of unexpected breakdowns.

Conclusion: Protect Your Fleet with Proactive Clutch Servo Care

A faulty clutch servo may seem like a minor issue, but its impact on your truck’s clutch operation can be profound. From increased driver fatigue to potential transmission damage and costly downtime, ignoring this component can jeopardize your fleet’s productivity and profitability.

At MAXTRUCK GROUP LIMITED, our commitment is to keep your trucks running smoothly with expert diagnostics, quality parts, and industry-leading service. Whether you’re facing clutch servo troubles or want to implement a preventive maintenance program, trust MAXTRUCK to deliver the solutions you need.

Don’t let a small part cause big problems. Contact MAXTRUCK today to schedule a clutch system inspection and keep your fleet moving forward.

| Common Clutch Servo Issues | Potential Consequences | Recommended Action |

|---|---|---|

| Stiff clutch pedal | Driver fatigue, improper clutch use | Inspect and replace faulty servo |

| Erratic clutch engagement | Premature clutch wear, transmission damage | Check servo and related components |

| Air/hydraulic leaks | Loss of clutch function, safety risks | Repair leaks, replace damaged parts |

| Difficulty shifting gears | Transmission wear, breakdowns | Comprehensive clutch system inspection |

For more information, expert advice, or to book a service, reach out to MAXTRUCK GROUP LIMITED today. Your fleet’s performance is our top priority.